What is laser drilling?

Laser drilling is a fast, efficient and economical non-contact method of accurately drilling holes into various hard, brittle and soft materials. The drilling medium is a high-power density beam of light requiring no physical contact between the cutting tool and the material. This in turn prevents contamination and expensive tool wear as seen with conventional tooling. High-energy Laser beam drilling is not limited by hardness, rigidity, or strength of a material. It is suitable for metallic and non-metallic materials that are generally difficult to process.

As always, when processing small holes, the ratio between hole diameter and thickness is an important index to measure. In the case of YAG Laser drilling, it is one of the few techniques available that can achieve a greater depth to diameter ratio than conventional mechanical drilling.

Sectors taking advantage of laser drilling

Due to its flexibility, laser drilling is suitable, but not limited, to sectors that require precise and economical material processing techniques. Manufacturers of circuit boards, turbine engines for aircraft propulsion and power generation, along with the automotive sector have all benefitted from the productivity provided by the development of Laser drilling and its ability to cut small holes at shallow angles to the material surface.

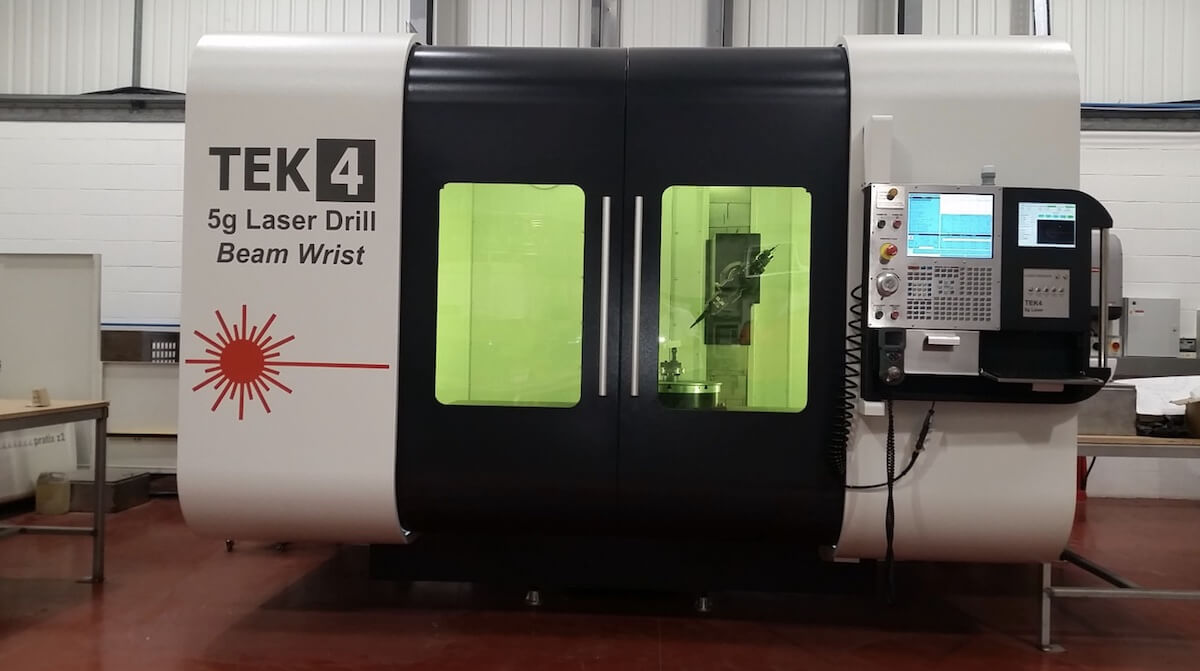

Our latest Laser system from TEK4 provides exceptional performance, rugged stability, and a straightforward user-friendly control. The machine features a single beam delivery mirror to ensure a stable beam of guidance, which allows for precise cutting. The sophisticated measuring touch probe allows for cost-effective machine calibration and component location.

Laser drill services at HSM Engineering Ltd

HSM Engineering Ltd can drill, cut, and weld 3D components in one set-up and the inbuilt measuring system gives us huge flexibility and aids compensation in regard to part variation. The machine uses a powerful, flexible and innovative palletizing location system that can hold with precision a wide variety of workpieces and allows for simple, responsive, and reliable repeatability.

We pride ourselves on being a progressive organisation with High Technology capabilities to provide engineering solutions in every sector. Let HSM Engineering Ltd take care of your metal and non-metal fabrication requirements.

0 Comments