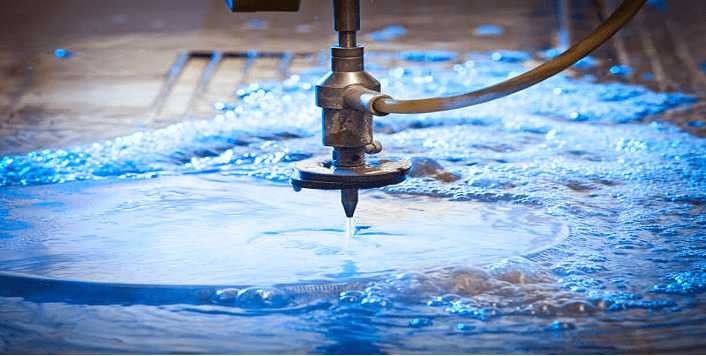

In industries like aerospace, defence and nuclear, precision and reliability are non-negotiable. When working with high-performance materials like titanium, Inconel, duplex, carbon fibre composites, and hardened steels, manufacturers need a cutting process that delivers accuracy without compromising material integrity.

At HSM Engineering, we specialise in high-precision waterjet machining, and we currently have specialist capacity available to support key industries and special projects.

Why Waterjet Cutting?

Waterjet technology offers several advantages over traditional machining methods:

- No Heat-Affected Zones (HAZ) – Unlike laser or plasma cutting, waterjet machining doesn’t generate heat, preserving material properties crucial for safety-critical applications.

- Extreme Precision – Capable of tolerances up to ±0.1mm, ensuring parts meet the strictest industry standards.

- Material Versatility – From lightweight composites in aircraft structures to radiation-resistant alloys in nuclear systems, waterjet cutting can handle it all.

- Eco-Friendly & No Tool Wear – A clean cutting process with minimal waste and no tooling costs.

Applications in Aerospace Defence & Nuclear

✅ Aerospace:

High-strength alloy components (titanium, aluminium, Inconel)

Carbon fibre-reinforced structures

Complex engine and structural parts

✅ Defence:

Armor plating – Military-grade steel and composite Armor cutting.

Aerospace defence – Fighter jet & UAV structural components

Naval & land systems – Precision parts for warships, submarines & military vehicles

✅ Nuclear:

High-precision stainless steel components

Heat exchangers and reactor internals

Radiation-shielding materials

Why Partner with HSM Engineering?

With our cutting-edge waterjet technology, skilled engineering team, and commitment to industry standards ISO 9001, AS9100, or GS3001, we are positioned to support critical supply chains in aerospace, defence, energy, and nuclear sectors.

If your project requires precision, reliability, and fast turnaround times, we’d love to collaborate.

Get in touch today sales@hucknallsheetmtl.co.uk

0 Comments